Description

Product Description

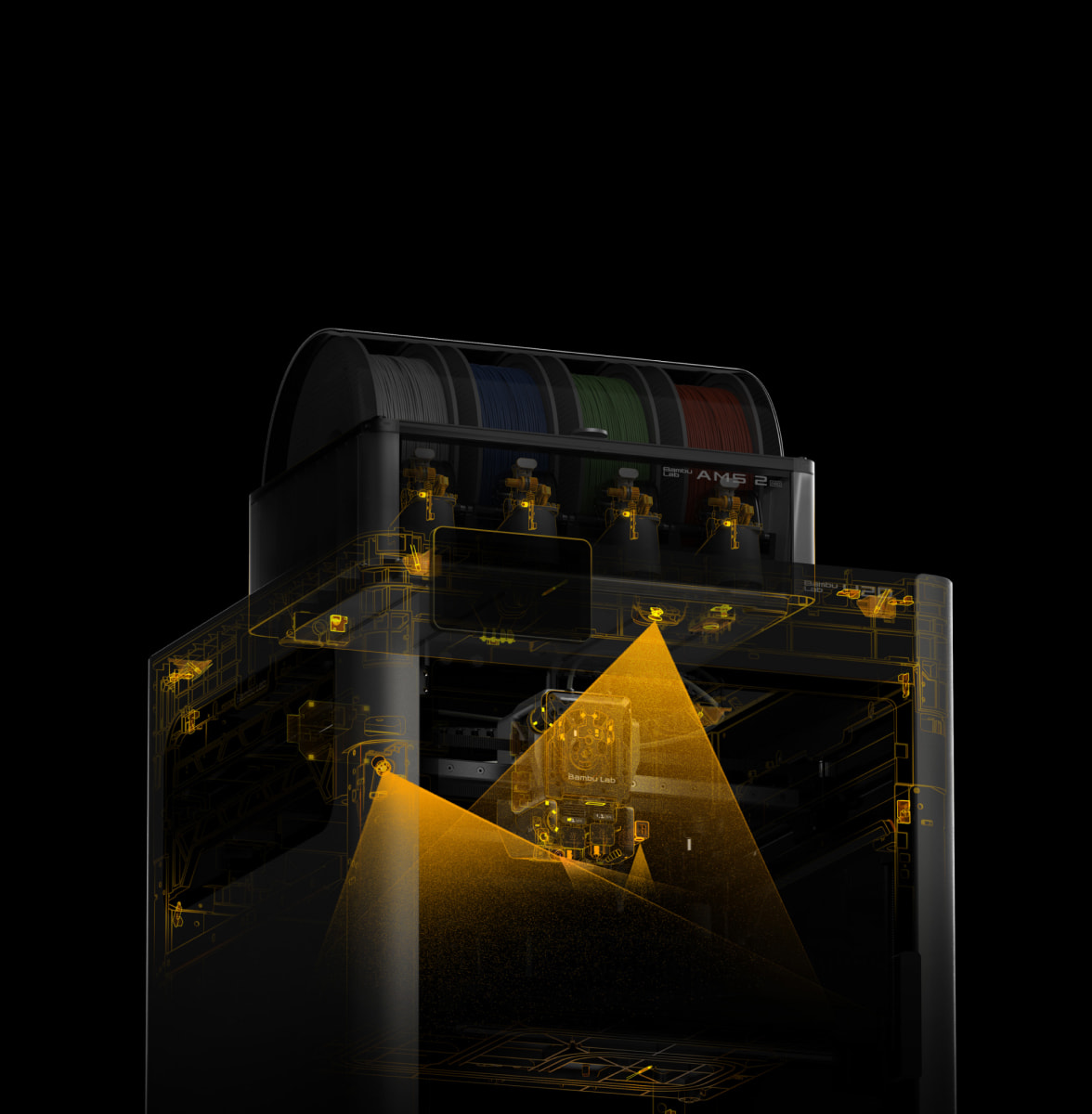

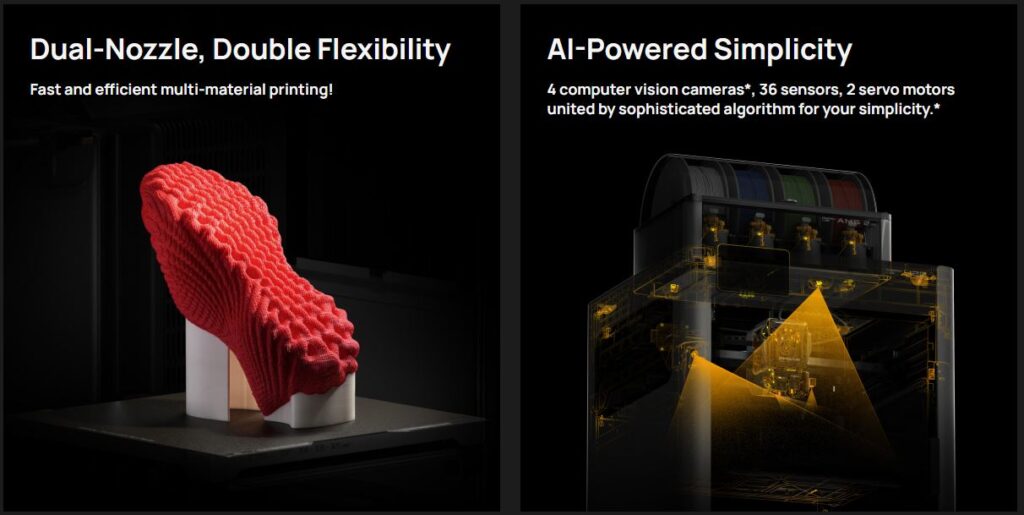

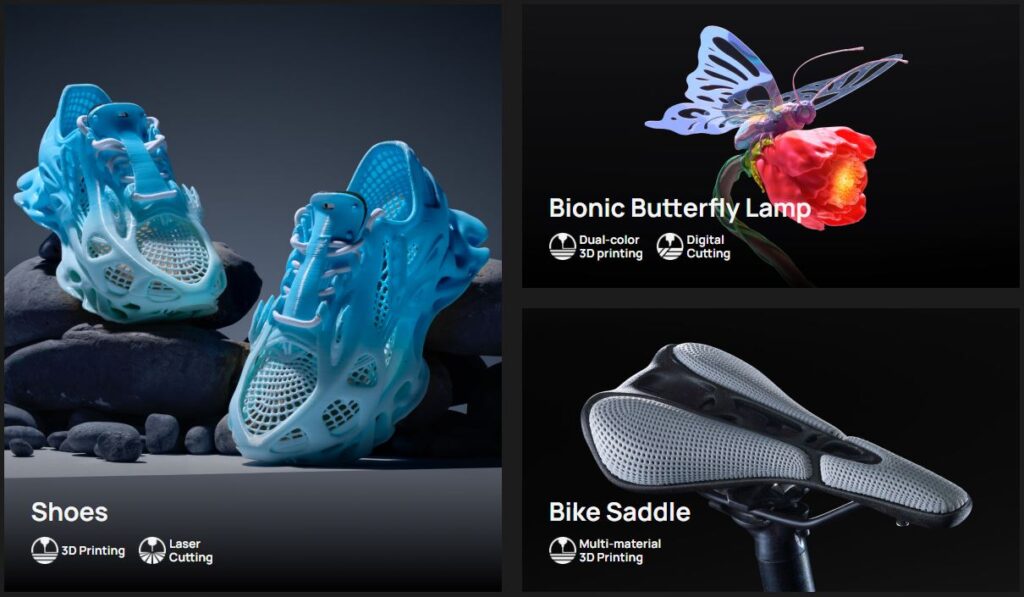

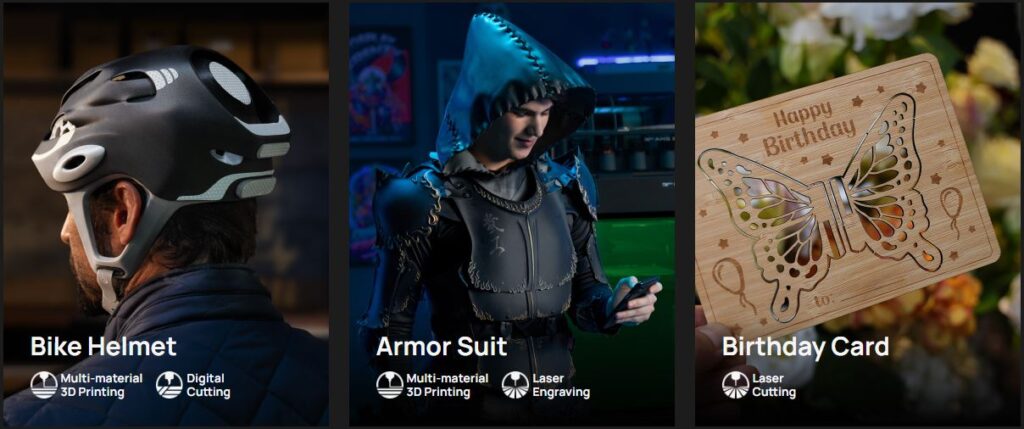

The Bambu Lab H2D is a personal manufacturing machine with a dual-nozzle system that supports multi-material and multi-color printing up to 350°C. It offers a 350 x 320 x 325 mm³ build volume, optional 10W/40W laser modules, and 5μm motion calibration for precise extrusion and detailed fabrication.

- Create vibrant multi-material prints effortlessly

- Engrave or cut materials with optional laser variant

- Master large projects with high precision

Personal Manufacturing Hub

Technical Specifications

|

Fused Deposition Modeling

|

|

Build Volume (W*D*H)

|

Single Nozzle Printing: 325*320*325 mm³ Dual Nozzle Printing: 300*320*325 mm³ Total Volume for Two Nozzles: 350*320*325 mm³

|

|

Chassis & Shell

|

Aluminum, Steel, Plastic and Glass

|

|

Laser Safety Windows

|

Equipped on Laser Edition, normal H2D can upgrade through Laser Upgrade Kit

|

|

Air Assist Pump

|

Equipped on Laser Edition, normal H2D can upgrade through Laser Upgrade Kit

|

|

Physical Dimensions

|

492*514*626 mm³

|

|

Net Weight

|

31 kg

|

|

Hotend

|

All Metal

|

|

Extruder Gear

|

Hardened Steel

|

|

Nozzle

|

Hardened Steel

|

|

Max Nozzle Temperature

|

350 °C

|

|

Included Nozzle Diameter

|

0.4 mm

|

|

Supported Nozzle Diameter

|

0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm

|

|

Filament Diameter

|

1.75 mm

|

|

Extruder Motor

|

Bambu Lab High-precision Permanent Magnet Synchronous Motor

|

|

Supported Build Plate Type

|

Textured PEI Plate, Smooth PEI Plate

|

|

Max Heatbed Temperature

|

120 ℃

|

|

Max Speed of Toolhead

|

1000 mm/s

|

|

Max Acceleration of Toolhead

|

20,000 mm/s²

|

|

Max Flow for Hotend (Standard Flow Hotend)

|

40 mm³/s (Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280 °C printing temperature)

|

|

Max Flow for Hotend (Optional High Flow Hotend)

|

65 mm³/s (Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280 °C printing temperature)

|

|

Active Chamber Heating

|

Supported

|

|

Max Temperature

|

65 °C

|

|

Pre-filter Grade

|

G3

|

|

HEPA Filter Grade

|

H12

|

|

Activated Carbon Filter Type

|

Granulated Coconut Shell

|

|

Part Cooling Fan

|

Closed Loop Control

|

|

Auxiliary Part Cooling Fan

|

Closed Loop Control

|

|

Chamber Heat Circulation Fan

|

Closed Loop Control

|

|

Cooling Fan for Hotend

|

Closed Loop Control

|

|

Main Control Board Fan

|

Closed Loop Control

|

|

Chamber Exhaust Fan

|

Closed Loop Control

|

|

PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, PET, Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA, PPA-CF/GF, PPS, PPS-CF/GF

|

Supported

|

|

Live View Camera

|

Built-in; 1920*1080

|

|

Nozzle Camera

|

Built-in; 1920*1080

|

|

BirdsEye Camera

|

Built-in; 3264*2448 (Equipped with Laser Edition)

|

|

Toolhead Camera

|

Built-in; 1920*1080

|

|

Door Sensor

|

Supported

|

|

Filament Run Out Sensor

|

Supported

|

|

Filament Tangle Sensor

|

Supported

|

|

Filament Odometry

|

Supported with AMS

|

|

Power Loss Recovery

|

Supported

|

|

Voltage

|

100-120 VAC / 200-240 VAC, 50/60 Hz

|

|

Max Power*

|

2200 W@220 V / 1320 W@110 V

|

|

Please purchase the version corresponding to your region’s voltage.

|

|

10 °C–30 °C

|

|

Touchscreen

|

5-inch 720*1280 Touchscreen

|

|

Storage

|

Built-in 8 GB EMMC and USB Port

|

|

Control Interface

|

Touchscreen, mobile App, PC App

|

|

Neural Processing Unit

|

2 TOPS

|

|

Slicer & Software

|

Bambu Studio, Bambu Suite, Bambu Handy Supports third-party slicers which export standard G-code, such as Super Slicer, PrusaSlicer and Cura, but certain advanced features may not be supported.

|

|

Supported Operating System

|

MacOS, Windows

|

|

Operating Frequency

|

2412-2472 MHz, 5150-5850 MHz (FCC/CE) 2400-2483.5 MHz, 5150-5850 MHz (SRRC)

|

|

Wi-Fi Transmitter Power (EIRP)

|

2.4 GHz: <23 dBm (FCC); <20 dBm (CE/SRRC/MIC) 5 GHz Band1/2: <23 dBm (FCC/CE/SRRC/MIC) 5 GHz Band3: <30 dBm (CE); <24 dBm (FCC) 5 GHz Band4: <23 dBm (FCC/SRRC); <14 dBm (CE)

|

|

Wi-Fi Protocol

|

IEEE 802.11 a/b/g/n

|

|

Laser Type

|

Semiconductor Laser

|

|

Laser Wavelength

|

Engraving Laser: 455 nm ± 5 nm Blue Light Height Measuring Laser: 850 nm ± 5 nm Infrared Light

|

|

Laser Power

|

10 W ± 1 W; 40 W ± 2 W

|

|

Laser Spot Dimension

|

10W: 0.03 mm * 0.14 mm; 40W: 0.14 mm * 0.2 mm

|

|

Working Temperature

|

0 °C–35 °C

|

|

Max Engraving Speed

|

10W: 400 mm/s; 40W: 1000 mm/s

|

|

Max Cutting Thickness

|

10W: 5 mm; 40W: 15mm (Basswood Plywood)

|

|

Laser Safety Class for Laser Module

|

Class 4

|

|

Overall Laser Safety Class*

|

Class 1

|

|

Engraving Area

|

10W: 310 mm * 270 mm; 40W: 310 mm * 250 mm

|

|

XY Positioning Accuracy

|

< 0.3 mm

|

|

Z Height Measuring Method

|

Micro Lidar

|

|

Z Height Measuring Accuracy

|

± 0.1 mm

|

|

Flame Detection

|

Supported

|

|

Temperature Detection

|

Supported

|

|

Door Sensor

|

Supported

|

|

Laser Module Installation Detection

|

Supported

|

|

Safety Key

|

Included

|

|

Ventilation Pipe Adapter Outer Diameter

|

100 mm

|

|

Supported Material Type

|

Wood, rubber, metal sheet, leather, dark acrylic, stone, and more

|

|

Cutting Area

|

300*285 mm²

|

|

Drawing Area

|

300*255 mm²

|

|

Supported Pen Diameter

|

10.5 mm-12.5 mm

|

|

Cutting Mat Type

|

LightGrip and StrongGrip Cutting Mats

|

|

Blade Type

|

45°*0.35 mm

|

|

Blade Pressure Range

|

50 gf-600 gf

|

|

Max Cutting Thickness

|

0.5 mm

|

|

Blade and Pen Recognition

|

Supported

|

|

Cutting Mat Type Detection

|

Supported

|

|

Supported Image Type

|

Bitmap and Vector Images

|

|

Supported Material Type

|

Paper, vinyl, leather, and more

|

FAQ’s

Can H2D be upgraded to H2D Laser Edition?

The H2D laser full combo has a built-in air pump and air pipe on the back of the printer, and is pre-installed with a BirdsEye camera. The front door, left and right side Laser Protective Windows, and top cover are all designed with laser protection. The packaging list includes a laser module, a cutting module, a smoke exhaust pipe and its adapter, as well as an emergency stop button.

Bambu Lab plans to launch a laser upgrade kit for the non-laser version of H2D. The upgrade kit is expected to be released in June and will also provide installation instructional videos to help users complete the upgrade smoothly.

It is important to note that the air pump in the upgrade kit is an external air pump, which has a different installation structure from the built-in air pump in the full set. When using it, it can only be installed externally and connected to the machine through an air tube.

Are the left and right hotends exactly the same?

Yes, the left and right hotends have identical structures and materials, and can be used interchangeably.

What is the maximum number of AMS 2 Pro and AMS HT units that the H2D supports? How many colors can it print at most?

The H2D supports a maximum of 4 AMS 2 Pro and 8 AMS HT connected simultaneously, a total of 12 units with 24 slots.

Because H2D is a dual-hotend printer, and in the most extreme scenario, all AMS can be connected to one hotend while the other hotend uses an external spool holder, it can support up to 25 colors.

Is H2D compatible with the first-generation AMS?

The first-generation AMS has been confirmed to have full plug-and-play compatibility and can be used with the H2D for multi-color printing, but it does not support the AMS drying function.

Due to the fundamental differences in the feeding mechanism and buffering structure, the H2D does not support the AMS lite.

AMS 2 Pro is directly connected to the printer through the 6-pin ports, so what are the two 4-pin ports on the back of the printer used for?

The two 4-pin ports on the back are reserved for future expansion accessories. For example, to upgrade a non-laser version of the printer to a laser version, one of these ports can be used to connect an external air pump.

Can I use the A1 series Hotend on the H2D? Conversely, can H2D hotends be used on A1 series printers?

Although the hotend of the H2D series is similar to the A1 hotend in structure , it is not exactly the same.

The H2D hotends are specifically designed for the H2D printer, offering optimized compatibility. For example, they support a larger maximum volumetric flow rate, lower clogging risk, more precise nozzle offset calibration between the left and right hotends, and automatic hotend type recognition via the live camera. Therefore, to ensure optimal print quality, it is strongly recommended not to use A1 hotends on the H2D printer.

Therefore , to ensure you get the best print quality, we strongly recommend that you do not use the A1 hotend for H2D printers.

Purchasing additional H2D hotends for use on A1 printers is feasible. However, you will also need to use the H2D hotend silicone sock.

What are the differences between the 10W and 40W laser modules? How should I choose?

Both the 10W and 40W laser modules are blue light lasers that support processing a variety of materials, including wood, rubber, metal sheets, leather, dark acrylic, and stone. However, due to differences in power and size, there are the following distinctions:

- Maximum cutting thickness(For Basswood Plywood):

- 10W laser module: 5mm

- 40W laser module: 15mm

- Maximum engraving speed(For Basswood Plywood):

- 10W laser module: 400mm/s

- 40W laser module: 1000mm/s

- Processable Area:

- 10W laser module: Maximum processing area X310mm * Y270mm, maximum processing height 280mm

- 40W laser module: Maximum processing area X310mm * Y250mm, maximum processing height 265mm

Is a USB included as standard? What functions are affected without a USB?

The package does not include a standard USB flash drive. You can still initiate printing normally without a USB, as the printer has built-in storage space to run print files.

However, without a USB inserted, the following functions will be affected:

- The recording and time-lapse photography functions can’t be turned on

- Printing cannot be initiated through the LAN

- Print files cannot be sent to the machine for storage through the studio

- Log files cannot be exported

USB2.0 protocol or above (actual minimum write speed needs to be greater than 10M/s), supported file formats are FAT32 and exFAT. And the printer only supports mounting one USB, and cannot connect multiple USB via a USB hub.

Why can’t I freely select hotend for printing with the printer’s built-in files?

The hotend to be used for printing has already been determined when the model file is sliced. As for the built-in models, the right hotend has been selected during the slicing process, so it is impossible to change the hotend used for printing on the printer screen.

When you slice the file in Bambu Studio and send the print task , you can freely choose to use the left hotend or the right hotend. For some filaments, such as TPU and PPS/PPA-CF, it is recommended to use specific hotends for printing.

For more details on H2D filament printing, please check the wiki.

Will the smoke and dust generated by laser operations affect my printer’s precision and lifespan?

H2D is equipped with an efficient exhaust system that effectively removes smoke and dust generated by laser operations, significantly reducing contamination. During R&D, we conducted rigorous testing to ensure that with regular machine cleaning, the impact of smoke and dust on performance and precision is negligible. For detailed cleaning instructions, please refer to this page.

How can I improve the success rate and quality of TPU printing?

Due to the flexible nature of TPU filaments, there are some operational issues that can arise during feeding and printing. To facilitate TPU printing, we have created a dedicated Wiki guide. Simply follow the instructions in the Wiki to successfully print with TPU filaments.

Are there any special safety precautions I need to take when using the laser function?

Because laser processing involves using high-energy lasers on potentially flammable materials, it’s strongly advised that users not leave their machine unattended during laser operations. Please maintain constant vigilance over the machine’s operational status and ensure that there are no flammable or explosive materials in the machine’s surroundings. For more information please refer here.