Description

Main Features

|

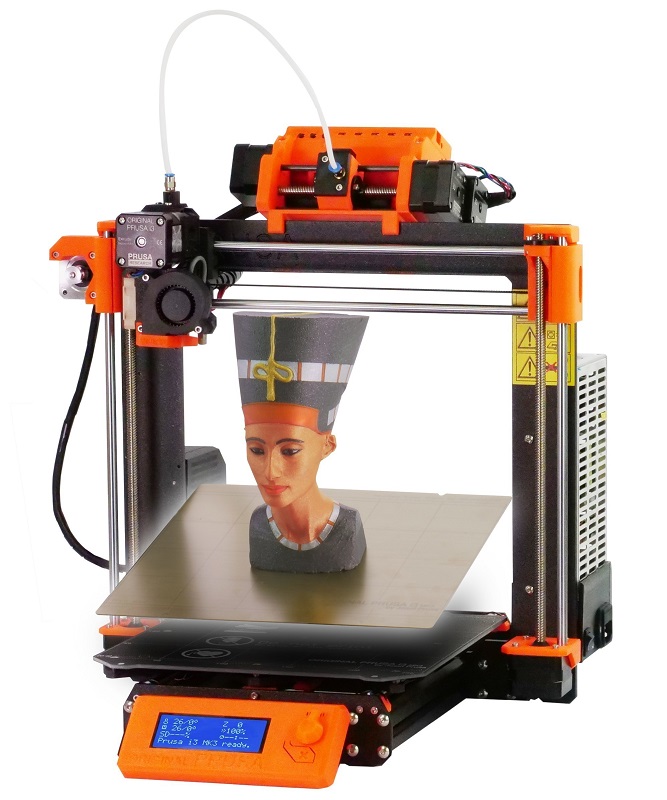

SuperPinda ProbeSuperPINDA probe features a hiqh-quality sensor for a fully-automatic Mesh Bed Leveling process. Before every print, the MK3S+ probes the bed in several places and creates a virtual heightmap of the print area. This process ensures that the first layer will always be spot on! |

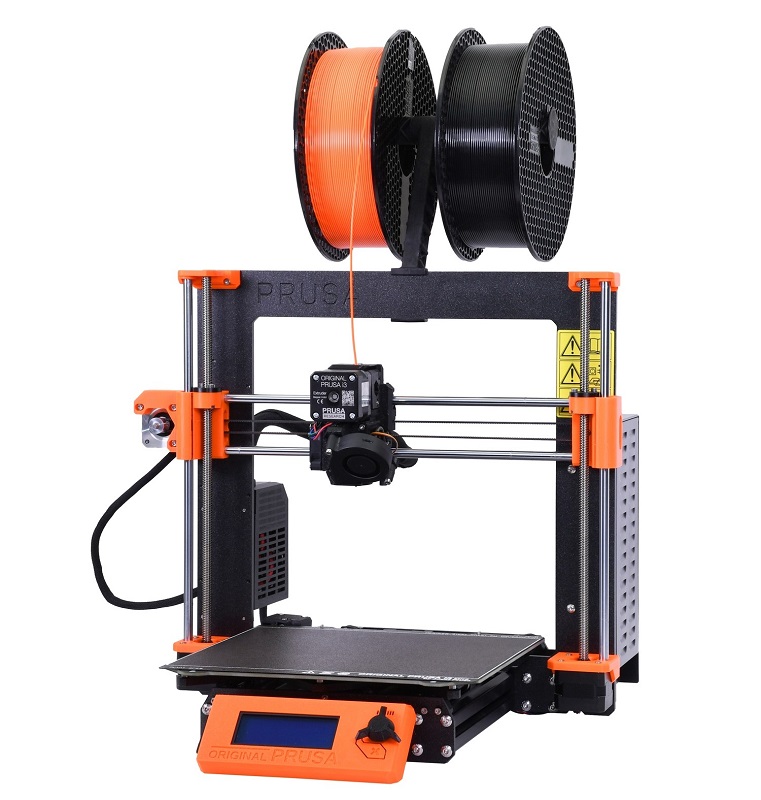

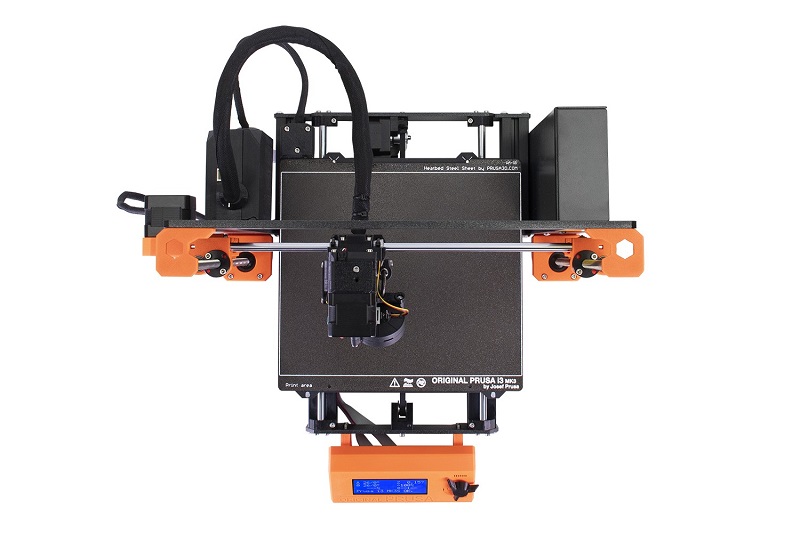

Misumi Bearings & moreThe MK3S+ features a new set of metal clips for the genuine MISUMI bearings on the Y-axis. The belt tensioning mechanism on the X-axis was reworked and the X-end plastic parts reinforced. The filament path in the extruder was altered for better support of flexible filaments. |

|

|

Removable Print SheetsSpring steel sheets are easy to maintain and make removing the printed object from the print surface a breeze. Prusa Research offer three types of print surface: smooth, textured and satin to cover all your needs when printing from a wide range of different materials – most of which do not require any special separation layers or surface preparation. |

High-Quality PartsThe MK3S+ features an aluminum extrusion Y-axis assembly. Thanks to the milled frame, the MK3S+ is stable, rigid, and easy to assemble. Combined with their internally developed extruder featuring Bondtech gears and the E3D V6 hotend, the MK3S+ can print high-quality objects up to 210 mm in height. |

|

|

Power Loss RecoveryAre you afraid of a blackout ruining your 48-hour print? Worry no more – the MK3S+ can deal with that! The printer can fully recover from the loss of power and continue printing exactly where it left off. It detects power interruptions and shuts down the heatbed and extruder heating, and saves the last known location. |

Filament SensorThe MK3S+ further enhances the reworked extruder from the MK3S. The built-in filament sensor uses a reliable trigger system, which detects whether a strand of filament is inserted into the extruder. It can detect any type and color of filament and is not susceptible to mechanical wear. |

|

|

Mesh Bed LevelingThanks to the SuperPINDA probe, the MK3S+ can use the Mesh Bed Leveling process to compensate for microscopic imperfections of the print sheet, and inconsistencies caused by the assembly and stacking of the manufacturing tolerances of various parts. Achieving a great-looking first layer is quick and easy. |

Slice with PrusaSlicerPrusa Research has their internally developed multiplatform slicer with in-house made and fully tested profiles for all of our 3D printers and a wide range of filaments. With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time! |

|

|

|

Support for a wide range of MaterialsThe MK3S+ is fully compatible with a wide range of various types of materials. No matter whether you want to print something for fun from PLA and flexible materials, or you need to produce durable prototypes from PETG, ASA, Polycarbonate and Polypropylene – the MK3S+ can handle them with ease. |

Open-source Hardware & FirmwarePrusa Research develops firmware for all of their 3D printers and test every new version thoroughly before release. Ongoing development and regular updates ensure that their machines are packed with useful features, such as print sheet profiles, automated calibration, Mesh bed leveling, advanced diagnostics, remaining print time estimation, Octoprint support and more! |

|

Technical Parameters

| Build Volume | 25×21×21 cm (9.84″×8.3″×8.3″) |

| Layer height | 0.05 – 0.35 mm |

| Nozzle | 0.4mm default, wide range of other diameters/nozzles supported |

| Filament diameter | 1.75 mm |

| Supported materials | Wide range of thermoplastics, including PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA/BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill and other filled materials. |

| Max travel speed | 200+ mm/s |

| Max nozzle temperature | 300 °C / 572 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| Extruder | Direct Drive, Bondtech gears, E3D V6 hotend |

| Print surface | Removable magnetic steel sheets(*) with different surface finishes, heatbed with cold corners compensation |

| Printer dimensions (without spool) | 7 kg, 50×55×40 cm; 19.6×21.6×15.7 in (X×Y×Z) |

| Power consumption | PLA settings: 80W / ABS settings: 120W |

* Consumable parts, such as PEI sheets (smooth, textured, etc.) are not covered by warranty as the coatings are designed to diminish over time unless failure has occurred due to a defect in materials or workmanship. Cosmetic damage, including but not limited to scratches, dents, cracks, or other cosmetic damage is also not covered by the warranty. Only defective sheets on arrival are covered by warranty.

Full Features List (October 2021 Edition)

- Controller: EINSY RAMBo 8-bit board with Trinamic 2130 drivers (256 microstepping), co-developed with Ultimachine, sensorless homing for X and Y axes

- Mesh Bed Leveling: Advanced high-quality SuperPINDA sensor (Super Prusa INDuction Autoleveling sensor)

- Print sheet profiles: Firmware supports print sheet profiles to store Live Z calibration data to enable quick switching between different print sheets.

- Filament sensor: IR sensor built-in, supports filament auto-loading. Print pauses when filament runs out.

- Power Panic: Hardware-based, single G-code line accuracy

- Ethernet connection: via Raspberry Pi (optional)

- Wi-Fi connection: via Raspberry Pi (optional)

- Advanced sensors: 3 thermistors, fans RPM monitoring, SuperPINDA

- Calibration: Automatic, Mesh Bed Leveling, SelfTest

- Print medium: SD card (16 GB card included)

- Firmware update: via PC (USB cable)

- PSU: Custom-made Delta PSU with hardware-based power panic

- Advanced features: Automatic filament loading, steel sheet profiles, Octoprint compatibility and more

- New features introduced through firmware upgrades